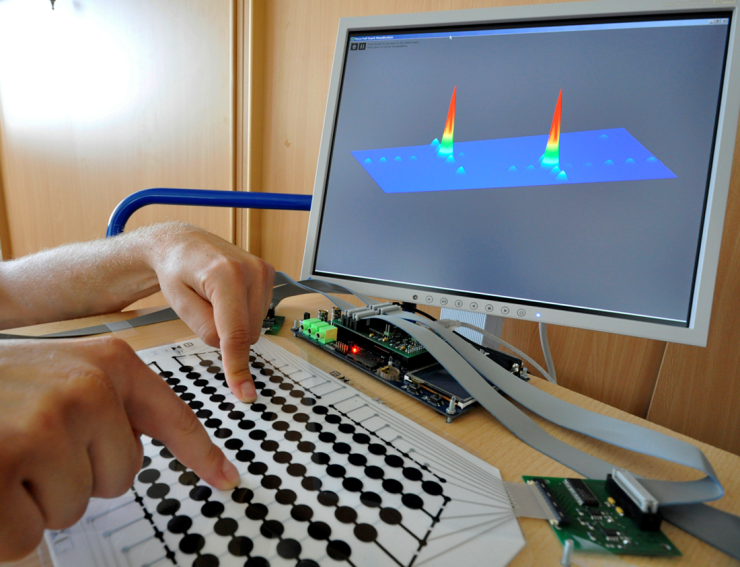

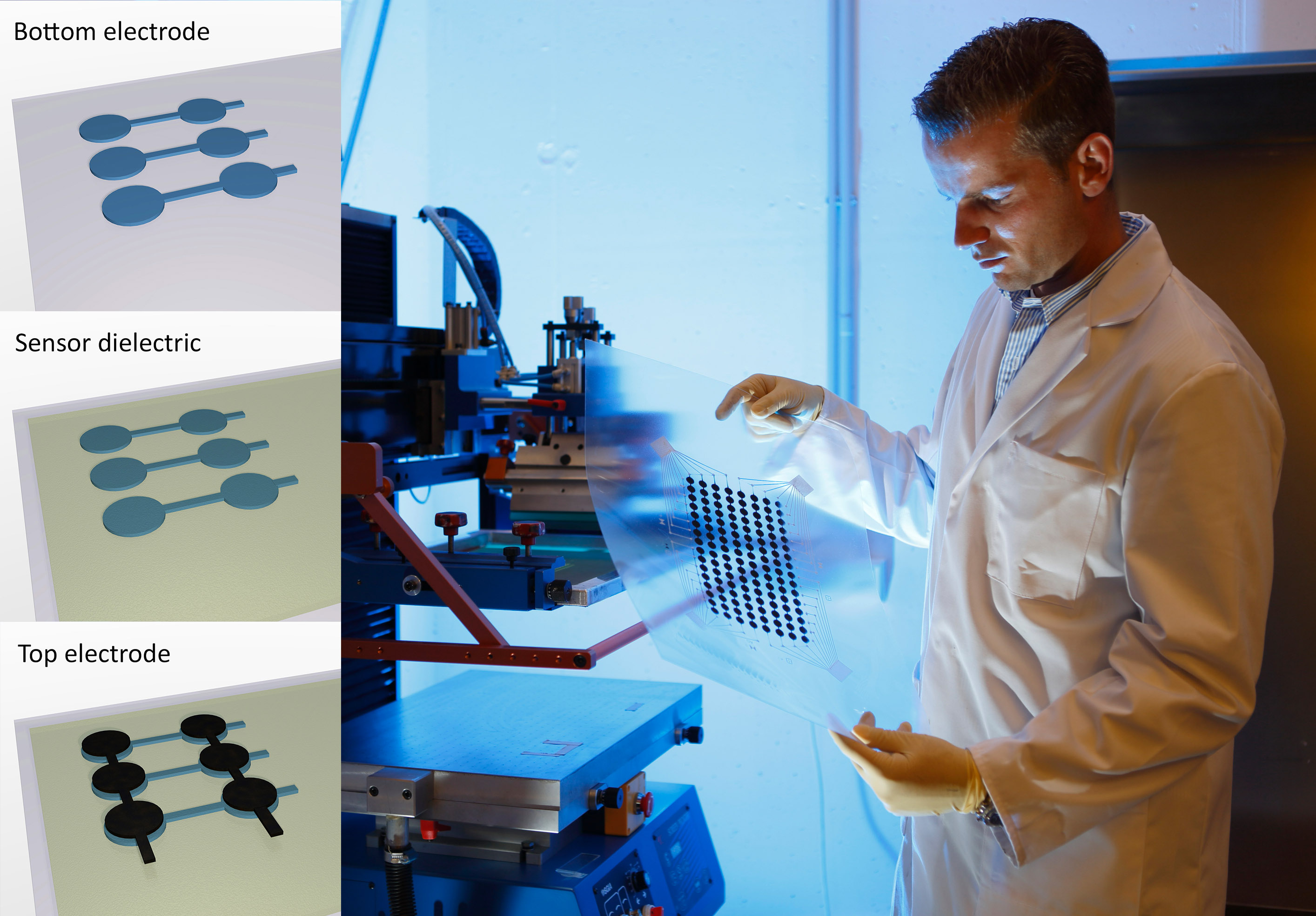

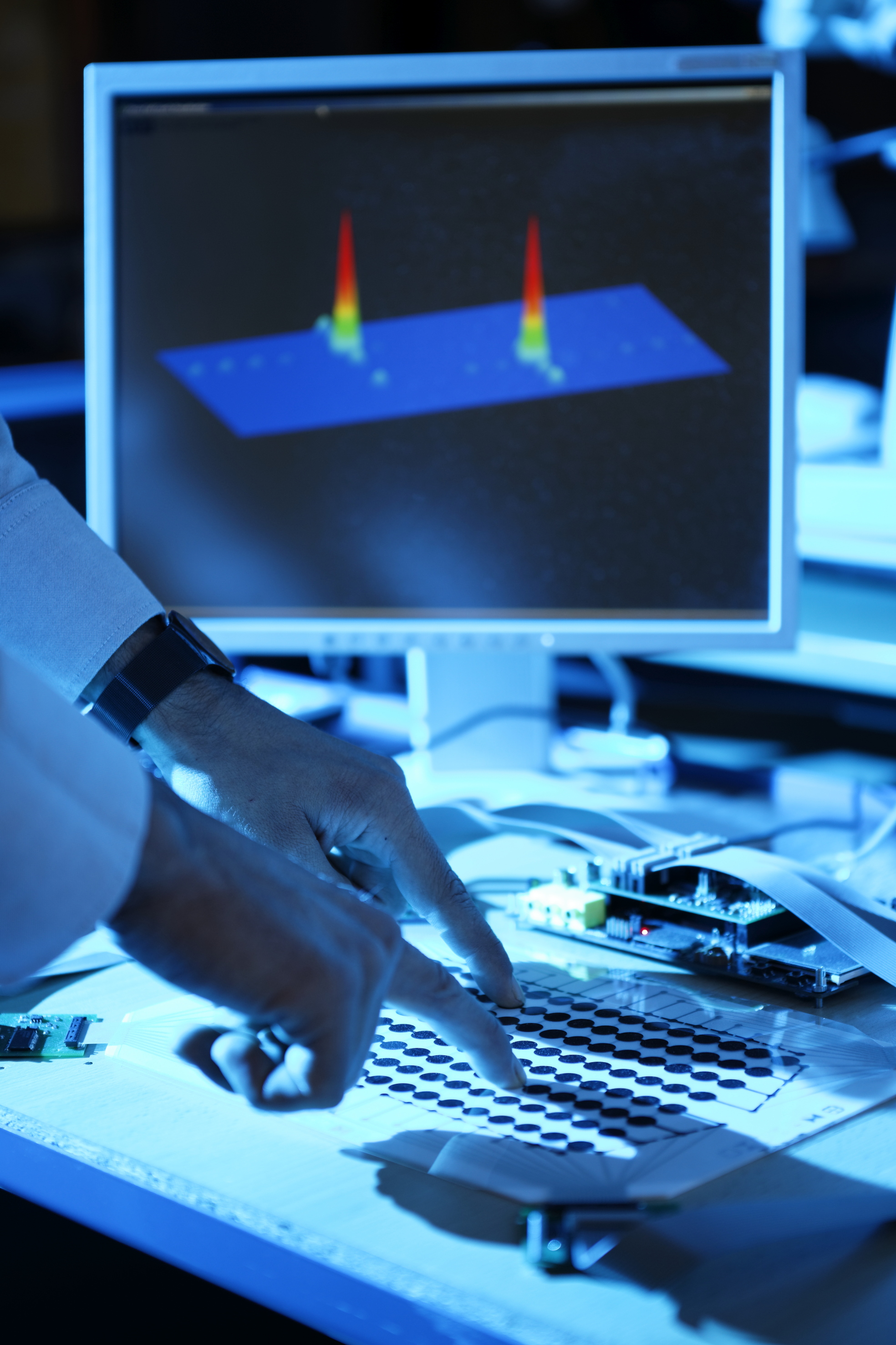

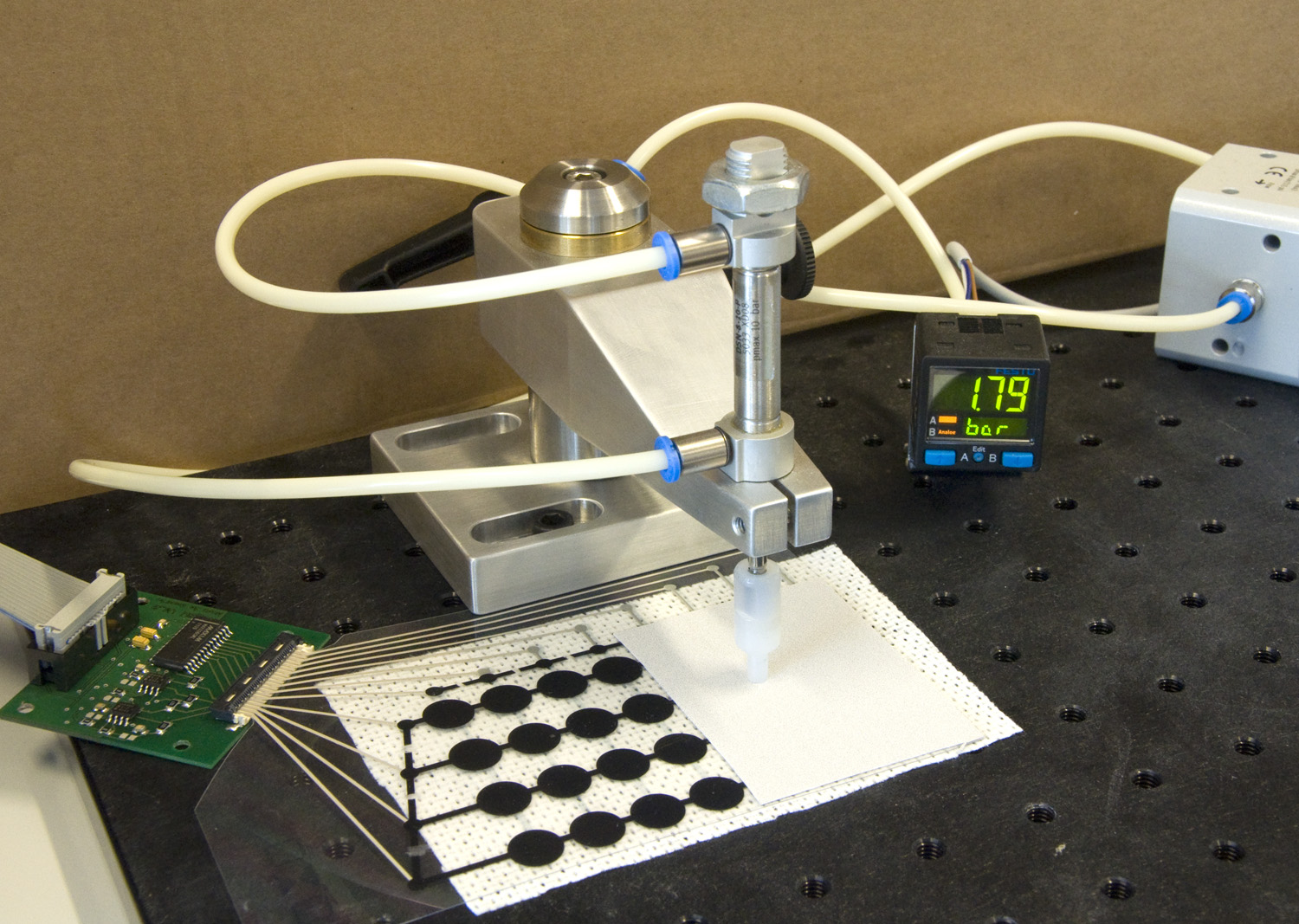

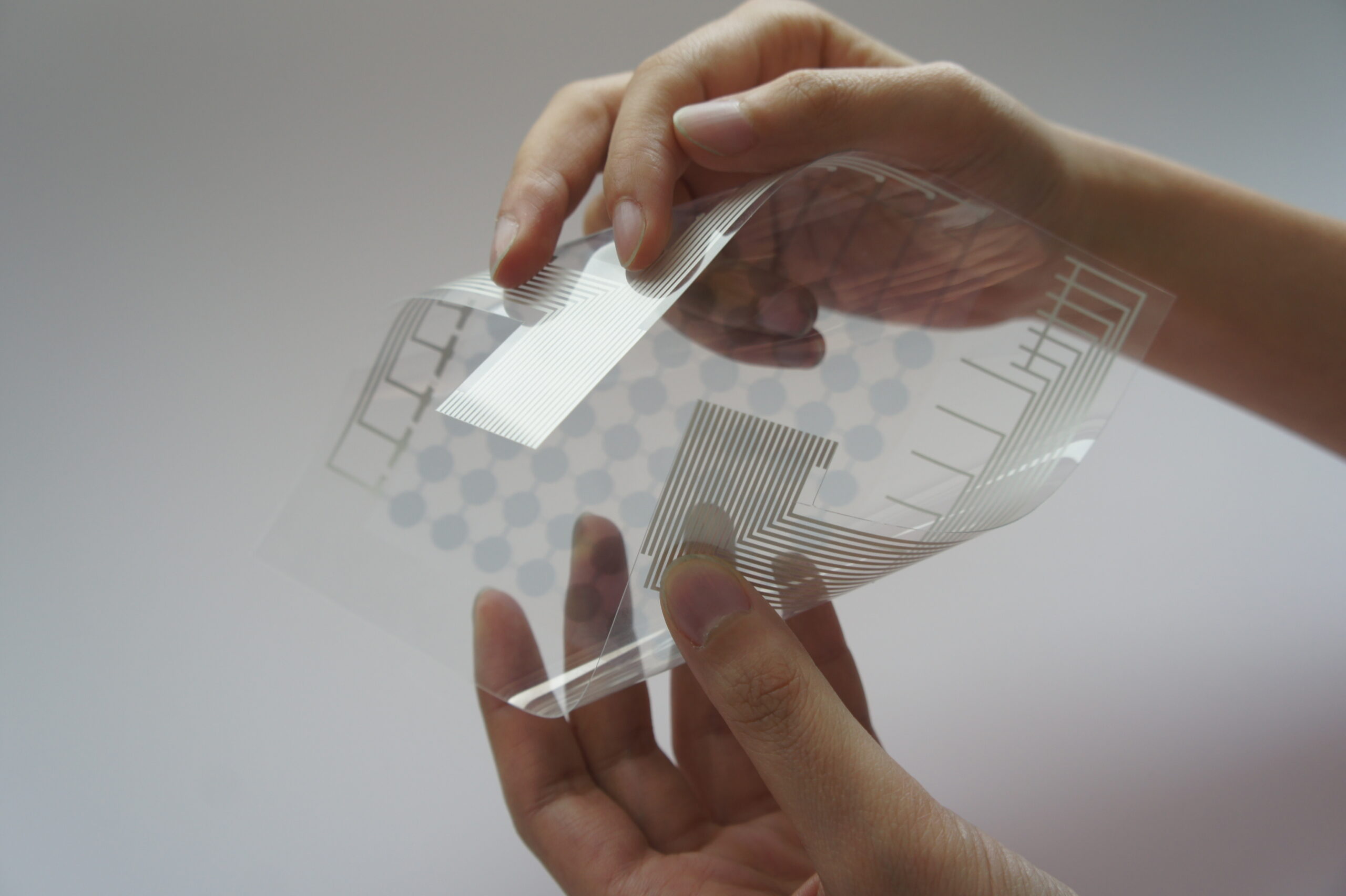

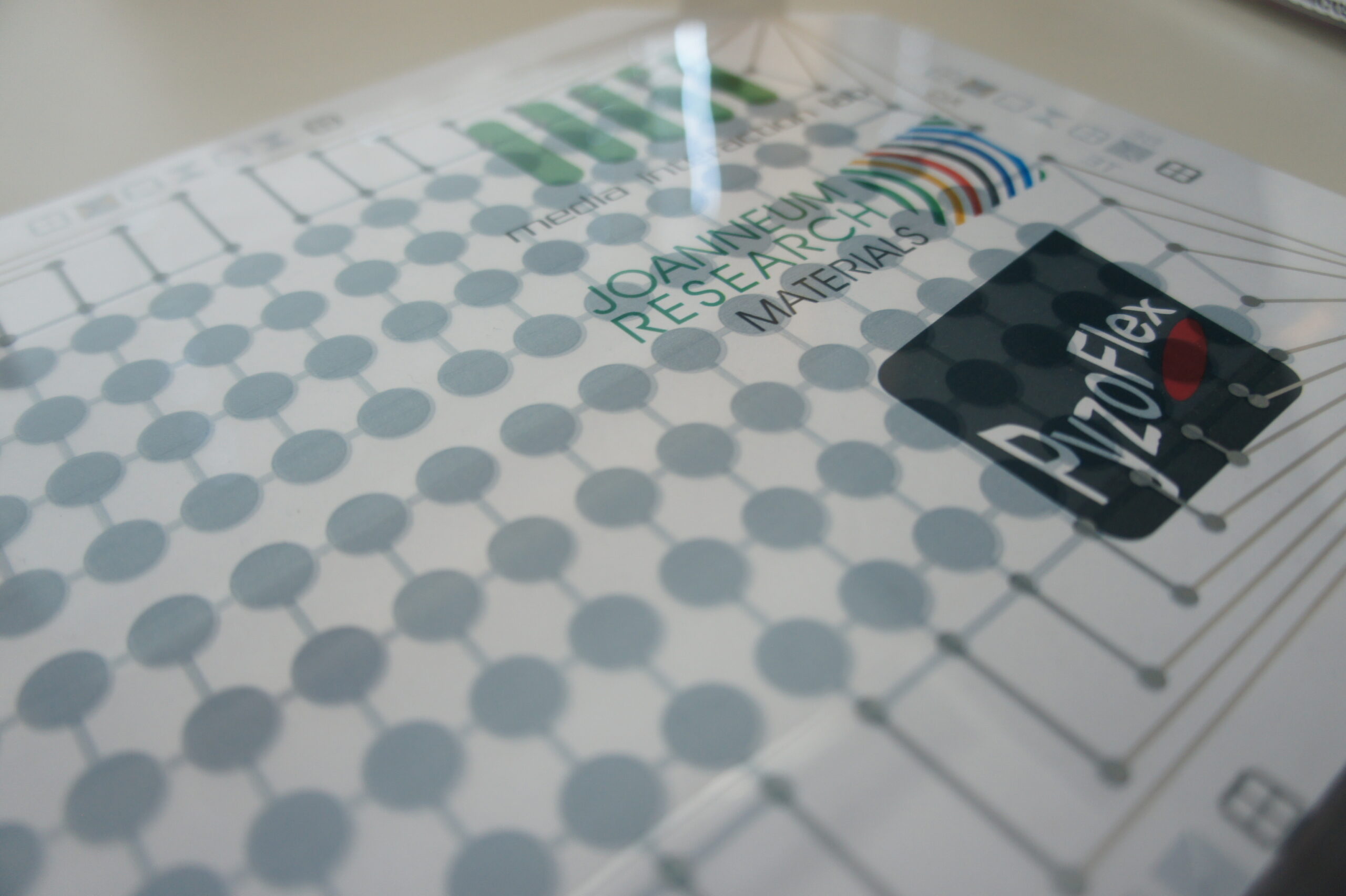

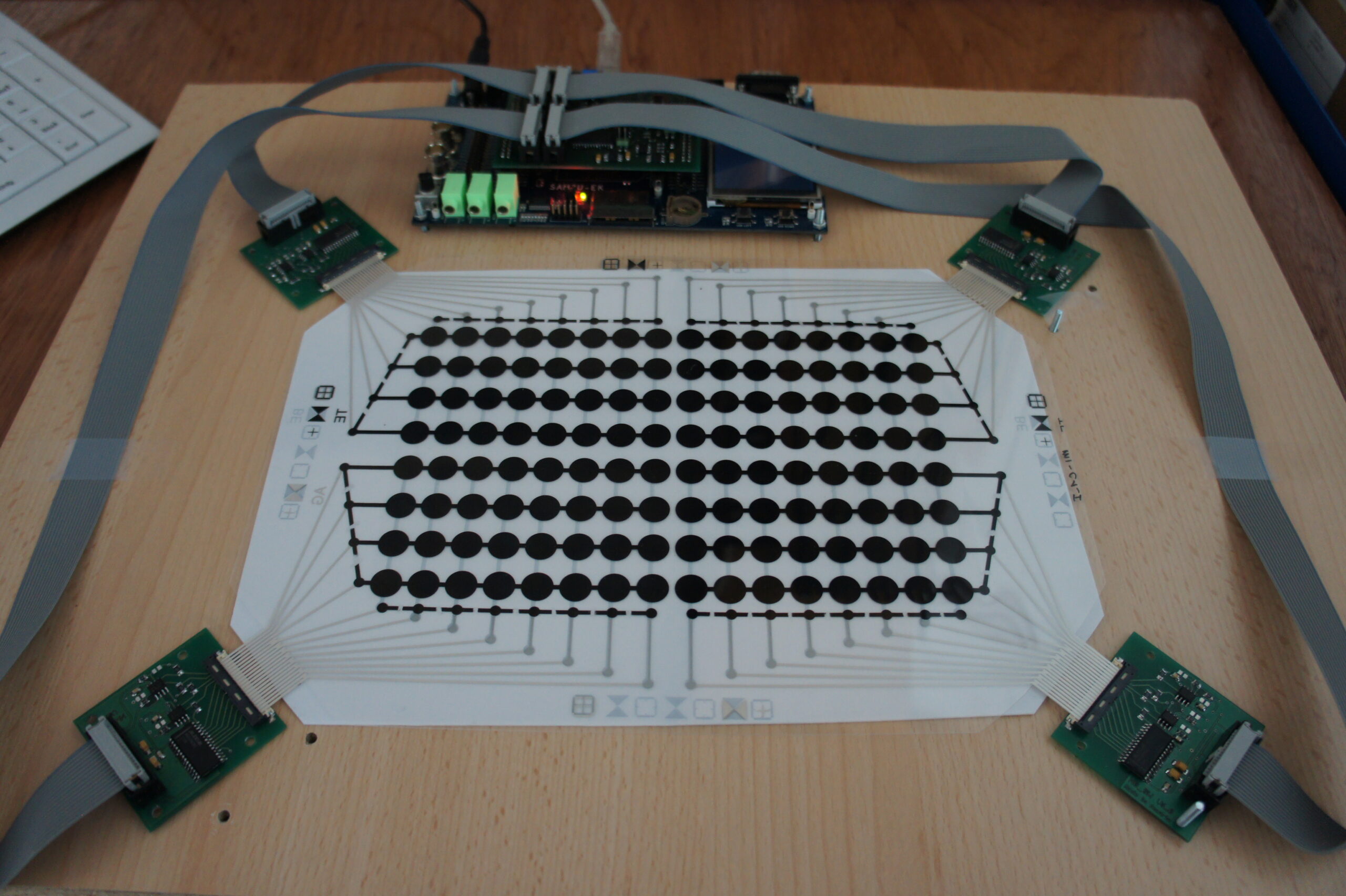

Over the last decade, touch sensing devices have become more and more important. Most researchers tried to improve multi-touch by introducing capacitive, resistive, or optical sensing devices. Although most of them provide already a multi-touch sensing, it is still often not possible to track input pressure efficiently. Tracking pen and touch separately in combination with pressure tracking provides new possibilities for user interfaces and interaction design: entirely new tools or even new interaction modes are possible due to the simultaneous use of pen and touch (e.g. touch input could be used for manipulations or navigation, whereas pen input could be used for accurate annotations). With ecoTouch, we present a novel sensing device that is based on a pyro- and piezoelectric sensor matrix that is screen-printed on a flexible film, and can detect changes in pressure and temperature respectively.