Since the RESi yarn, a metal wire coated with piezoresistive enamel, was the initial building block of TextileUX, our focus was on the development of driver electronics that are capable of a high number of resistive sensors that are embedded in textiles.

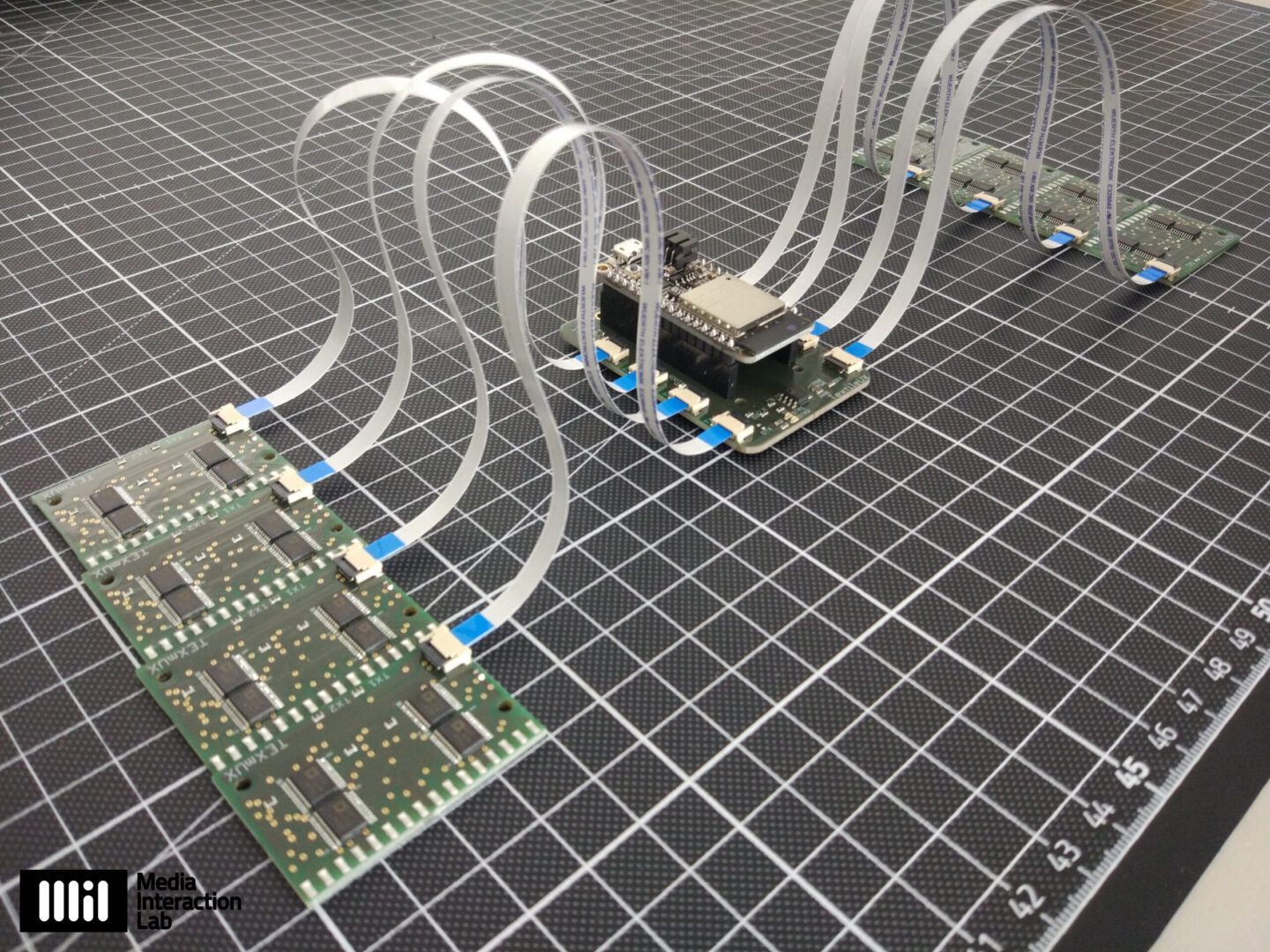

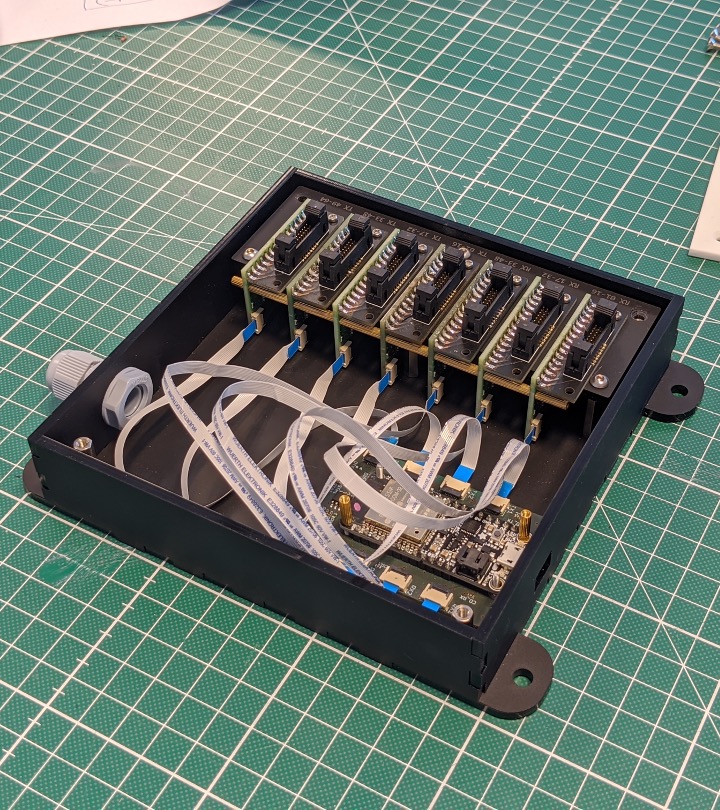

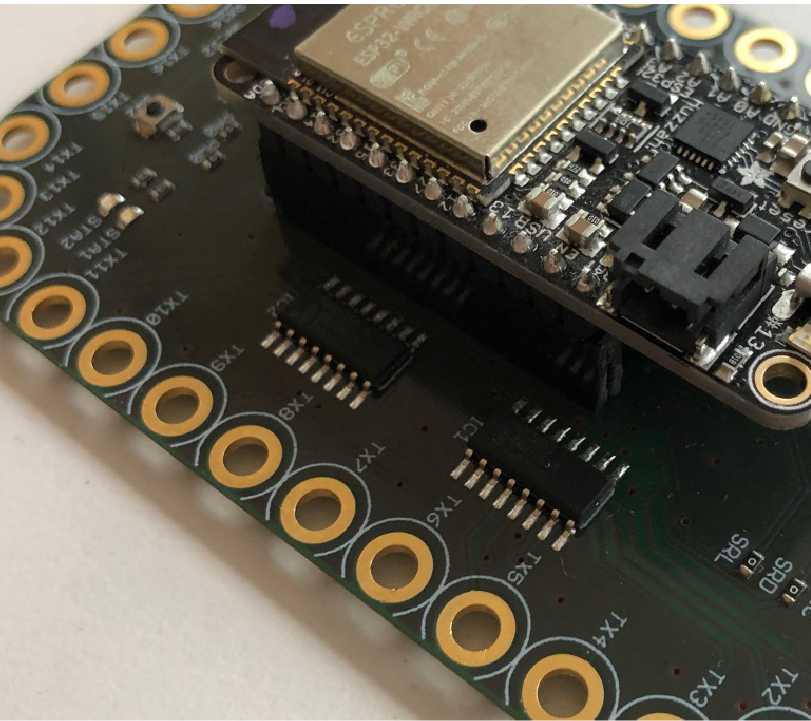

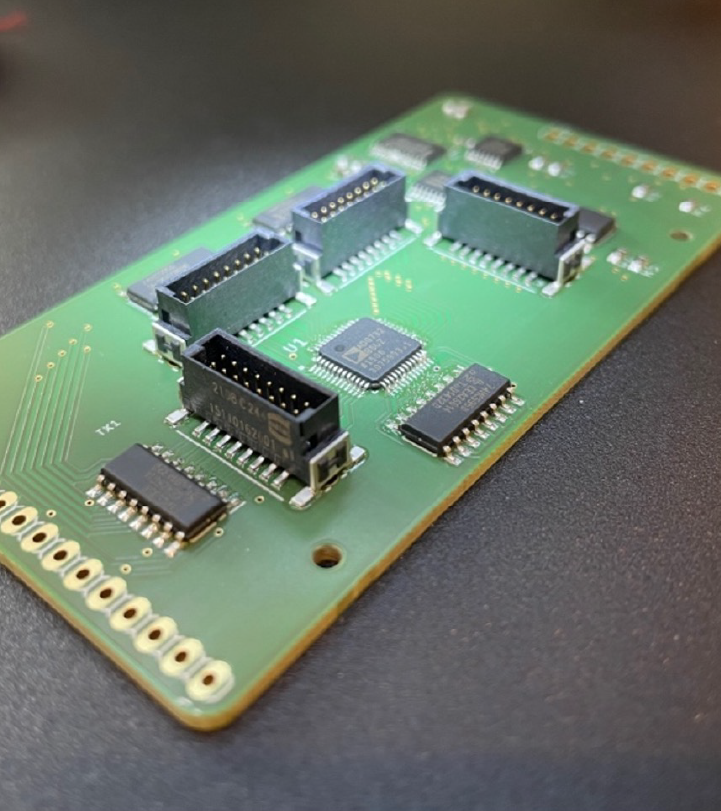

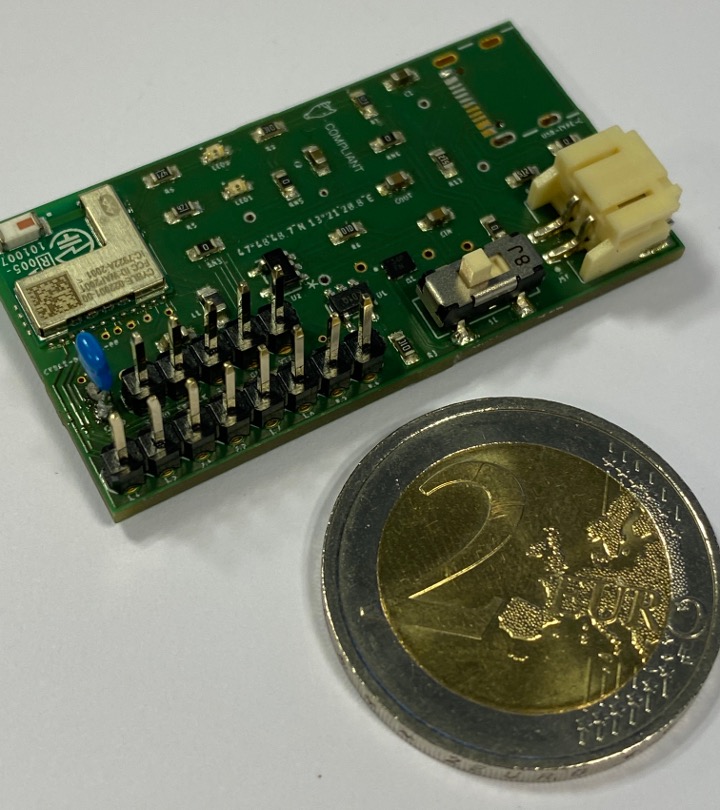

The first hardware we designed with scalability and high readout speeds in mind. It features a modular design and consists of a single main board for fast data acquisition and multiple extension PCBs that allow routing of a large number of sensor electrodes. This setup is highly flexible in terms of sensor dimensions as it is able to scale seamlessly from single sensors to matrices of up to 64×64 sensors. To sample the resistive sensors, we use shift registers in combination with analog matrix switches. The shift register applies voltage to individual rows, while the matrix switches sequentially connect each column to the ADC via a voltage divider. We furthermore include a digital potentiometer, to dynamically adjust the pull-down resistance in the firmware. This allows for adaptive sensing by adjusting to individual sensors with varying resistance changes. An Espressif ESP32 microcontroller is used to acquire sensor data, perform basic pre-processing, and sending data to a host device via USB, Wifi, or Bluetooth.