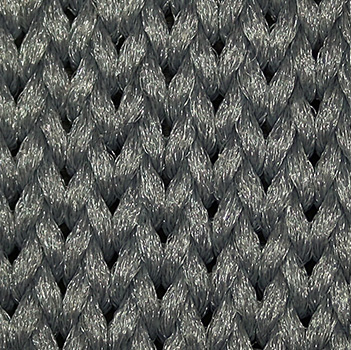

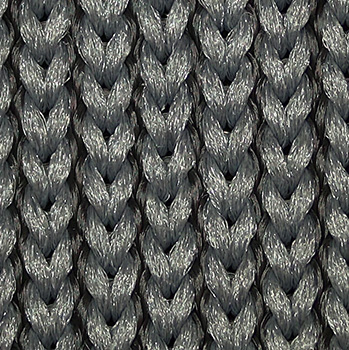

Most practitioners and researchers in the field of knitted strain sensors use highly stretchable structures, such as Plain (aka. Single Jersey), Double Jersey or variations of rib patterns. However, many scenarios require higher tensile stability, or even anisotropic elasticity, most notably in use cases beyond garments.

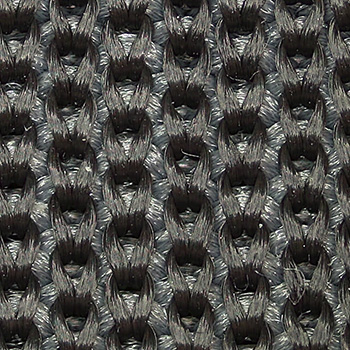

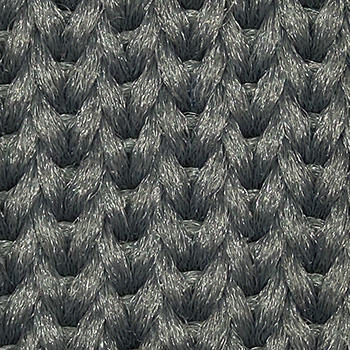

Together with our friends at STOLL, we investigated so-called Twill knits, which occupy only a single needle bed and can therefore be advantageous over Cardigan, Milano, or Interlock patterns. We systematically optimized the performance of our sensors by studying a large number of variations, including Intarsia and tubular structures. We modified stitch settings as well as thread count and material compositions, and compared options of connecting front and back faces, to provide support for the sensing parts.

A major learning is that the improvement of elastic recoil, which is achieved by addition of Lycra to the substrate yarn, is highly beneficial to the sensors’ consistency and counteracts wear-out effects. Furthermore, connecting sensor and substrate faces using tuck stitches can yield superior results, however the tucking direction is paramount: tucking the sensing face to the substrate, instead of the reverse, resulted in defective sensors. Refer to the full IEEE Sensor Journal paper (Open Access) for more details.

Also, check out a related project that shows how we further improve sensor data by computational means, utilizing Machine Learning techniques to mitigate inconsistencies in the raw sensor data.

The numerous swatches used for this study were knitted by KARL MAYER | STOLL Textilmaschinenfabrik GmbH.